Repol from Valjevo to build new waste recycling facility – Production capacities to double

Tuesday, 16.07.2019.

Tuesday, 16.07.2019.

10:01

10:01

The planned facility in Valjevo, which is meant for production, business operations, as well as storage and logistics, should have an area of 4,025 m2. As they told our portal, they already have a contract signed with the design studio Valjevoplan on the preparation of project documentation, as well as contacts and offers from several potential contractors and they are waiting for the realization of the investment to begin this October, after the best bidder is selected.

Repol has received the funds for this investment, worth RSD 62,500,000, from the Development Fund of the Republic of Serbia, through the credit program for the boosting of entrepreneurship.

Dejan Micic, the company's director, an engineer of technology by profession, says for our portal that the company aims to move the production, storage and logistics from the current location, which they are renting, which is why Repol is to build its own energy efficient production space.

– We would move the current two Erema lines and other equipment we have, that is, all our current production, to that space, which would enable us to get a new line and develop further in 2 to 3 years, as well as to connect to the current substations of 35 MW for the new Industrial Zone.

As Micic pointed out for eKapija, this facility will also increase their production capacity, which already increased by around 50% in 2018 with an additional line in Valjevo and a new facility in Vrsac.

– Repol has continued its intensive development. In late June 2018, we commissioned the new Erema Intarema 1108 TVE Plus line in Valjevo. Also, the Repol PJ facility in Vrsac was put into operation. The capacity of regranulation therefore increased from 300 to 500 tons in Valjevo, whereas, in Vrsac, the monthly capacity is 600 tons. This business-production facility we are building in modules will have all the infrastructure needed for the production to double, that is, to increase from the current potential 500-600 tons to around 1,200 tons a month – Micic says.

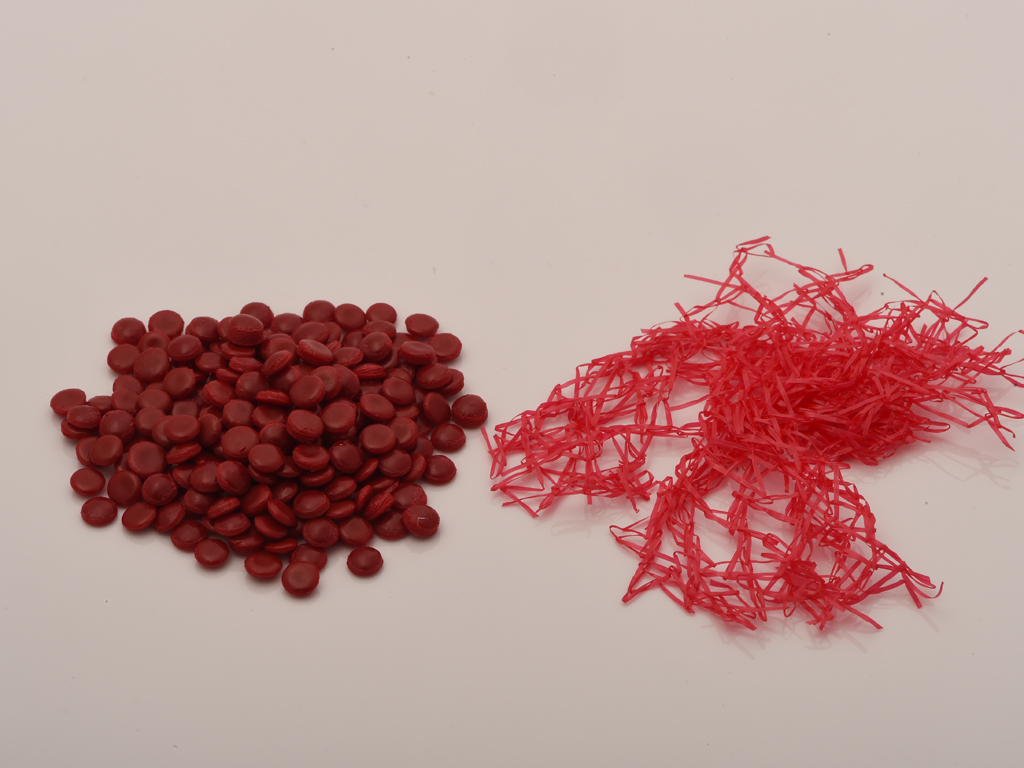

When it comes to the production of regranulates, Micic says that regranulates can replace the much more expensive original granulates.

– It's clear that the production of original granulates irretrievably consumes fossil fuels and large amounts of electrical energy, while also polluting the environment, whereas recycling or regranulation is merely turning the shapes in which polymers are used now into the shape of regenerates or regranulates, where they can be reused.

As he adds, although it is not profitable to be in certain segments of recycling at the moment, such as collection and transport, as well as the washing and the regranulation of used foil, whether alone or in a partnership, Repol might develop a project of the washing and the regranulation of used consumable packaging foil.

– The prices of finished products such as construction foils and garbage bags have dropped considerably, and there's also the hyperproduction of such regranulates, which spills over into Serbia as well. The fact is that Repol has enough expert knowledge and business connections in the EU to be able to develop, alone or through a partnership, a project of the washing and the regranulation of used packaging foil. However, this is not an economically sustainable project by itself and it requires subsidies.

She adds that they are also counting on the possibility of getting grants in the field of environmental protection, as Serbia is on its way to joining the EU and the biggest investments and grants will be available within that chapter.

– I can cite the examples of Bulgarian and Romanian companies which are comparable to Repol and which have received grants for the purchase of equipment in the amount of 70% each, or companies from Croatia, which get 50% in various forms from EU funds.

Reduction of CO2 emission

– With the line that we have – Intarema 1108 TVE Plus Eco Save, the projection is for savings of 367,500 kWh and a reduction of CO2 emission by 228 tons to be realized through working in three shifts, with 42,000 hours a year and a regranulation of around 1,500 tons a year – Micic said.

He pointed out that the company exported continually each year to its clients in former Yugoslav countries directly or the EU, directly or through Serbian companies. In 2018, the direct export to clients in Bosnia and Herzegovina, Italy and the Czech Republic, was worth EUR 327,869.

S. Petrovic

REPOL d.o.o. Valjevo

REPOL d.o.o. Valjevo

Fond za razvoj Republike Srbije Niš

Fond za razvoj Republike Srbije Niš

Most Important News

06.04.2024. | Agriculture

Preconditions for Placement of Fresh Blueberries and Dried Plums in Chinese Market Secured

16.04.2024. | News

Jovan Ciric, Leasing Director Retail MPC Properties – MPC Echo symbolizes our desire for good ideas and innovative endeavors to spread freely and bring about positive changes

16.04.2024. | News

10.04.2024. | Finance, IT, Telecommunications, Tourism, Sports, Culture

Creative Industry – What This Serbian Economy Sector Worth EUR 2 Billion Encompasses

10.04.2024. | Finance, IT, Telecommunications, Tourism, Sports, Culture

18.04.2024. | Industry, Finance

Here come the new hunters for Serbian gold – Australian Strickland Metals buys mining project on mountain Rogozna

18.04.2024. | Industry, Finance

16.04.2024. | News

Economy Fair in Mostar opens – 26 companies from Serbia exhibiting

16.04.2024. | News

18.04.2024. | Transport

Jovanovic: Purchase of Siemens trams produced in Kragujevac for GSP Beograd should be considered

18.04.2024. | Transport

Izdanje Srbija

Izdanje Srbija Serbische Ausgabe

Serbische Ausgabe Izdanje BiH

Izdanje BiH Izdanje Crna Gora

Izdanje Crna Gora

News

News