(NOMINATION FOR AUREA 2017 AWARD):Hydrogen Technologies - Machine for de-carbonization of combustion engine with oxygen

Tuesday, 21.03.2017.

Tuesday, 21.03.2017.

14:29

14:29

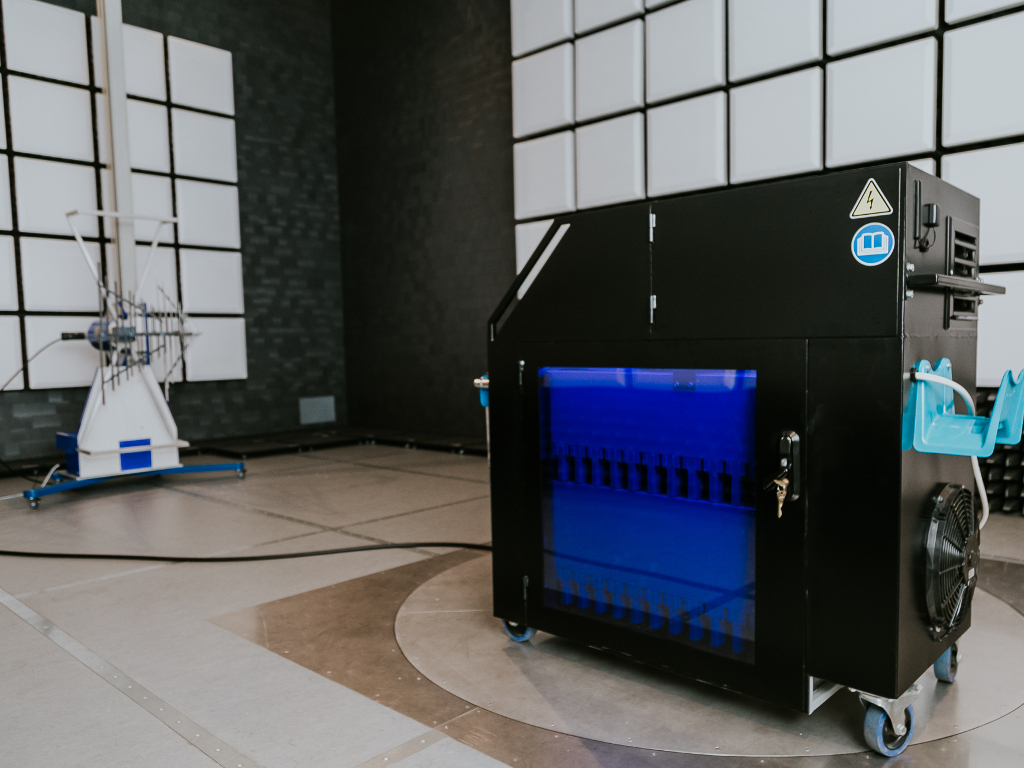

Belgrade-based company Hydrogen Technologies has developed and put on the market a unique technology for removing soot from engines and vehicle exhaust systems. Large amounts of the HHO gaseous mixture act as the main “energy source” for engine cleaning. The mixture is produced through an electrochemical process of water electrolysis. A machine was made for that purpose, containing, in addition to electrical energy assemblies, also a product of local creativity, a large-capacity HHO gas generator, unique in the world for its technical characteristics of energy efficiency, currently in the process of being protected as intellectual property.

The implementation of the technology considerably reduces the emission of toxic gases, and, following a 45-minute treatment, engines soil all other assemblies far less, extending their life cycle, making for a noticeably smoother performance and increased power, and an enormous percentage of vehicles also spend less fuel.

After three years of development and testing, the company opened the first Engine Decarbonizing Center in Belgrade in May 2016. The center provides service and further development and will also act as a Show-room for potential partners and associates.

The first orders from abroad have also arrived and three machines have been sold in Germany, Great Britain and Macedonia. In addition to mastering the process of engine decarbonizing machines, which should be adapted and offered to the automotive industry market, the vehicle and engine maintenance industry, as well as motor vehicle testing companies, Hydrogen Technologies plans to further expand the network of engine decarbonizing centers, as well the franchise concept of operations in the territory of Serbia, the region and Europe, for which they've already found a partner from Poland.

INNOVATION

At the time the project started, only one company from the Middle East was offering HHO-based Engine Carbon Cleaning machines. The problem was that water electrolysis cells, which are at the heart of such machines, have low energy efficiency and small HHO production capacity, disabling them from cleaning IC engines of higher volumes.

The problem with the currently available machines is that they in fact require too much electricity for electrolysis cells for the amount of gas produced measured in cubic meters, which drops even further with time. The American Hydrogen Association prescribes that, from the angle of energy efficiency, good cells use no more than 250 Wh for a liter of gas. While machines made by the competition require 250, 500, or even 1000 Wh, the Belgrade company's machine needs only 155 Wh, which is far below the amount prescribed for energy efficient water electrolysis in the US.

The technology developed by Hydrogen Technologies is a specific technical solution for the water electrolysis cell, featuring remarkably high energy efficiency, allowing for the production of quality HHO, a large number of repetitions in the course of a single day, as well as high cell durability.

The cleaning process begins by placing a hose from the machine into an idling engine. The hydrogen reacts with carbon, turning soot into hydrocarbon, which exits the engine in a gaseous state through the exhaust system without soiling other car elements in the process (engine oil, DP Filter, catalytic converter, turbines, sensors etc.).

The machine doesn't need to work for more than 30 to 45 minutes, and measurements made only half an hour after decarbonizing show a reduction of exhaust gases and soot by 50-93% in diesel engines, which is considered a very important issue throughout the world as soot particles are extremely cancerous. At the same time, the power of the engine increases, as does its torque, whereas fuel expenditure and vehicle maintenance costs are reduced.

Along with the machine itself, the engineers of Hydrogen technologies have developed a PLC (Program-Logistics Controller), an electronic control unit for the machines, as well as a GPRS system of controlling the machine wherever it is. This means that each machine, no matter its location, can provide information about its position, degree of usage, number of engines cleaned or whether the water has been poured. Furthermore, the machine will sound the alarm in case anything is malfunctioning. By purchasing the machine, the users also gets a 3-year maintenance service, with potential interventions made within 72 hours.

Hydrogen technologies points out that neither the local nor the foreign public are too familiar with the technology of producing hydrogen from water and its implementation in IC engines, as proven by the fact that they were the first officially registered company in Europe producing hydrogen generators for implementation in the automotive industry.

SOCIAL

USEFULNESS

The idea of Engine Decarbonizing arose during the testing of the possibility of speeding up the engine cleaning process to 30-60 minutes by increasing the amounts of HHO, thereby producing the said effects, which are very important for the human environment and the amortization and expenses of vehicle exploitation.

The results made so far (user feedback) have shown that, in addition to benefits to the vehicle itself (improved engine running, reduced fuel consumption, less dirt on the components leading to fewer problems and reduced vehicle maintenance costs etc.), decarbonizing also has a great effect in promoting the importance of reducing negative environmental impact. The process, then, increases environmental awareness, reduces negative environmental impact and allows end users to reduce expenses all at the same time.The engine decarbonizing machine is fully a result of the local know-how. It was developed by local experts, the Hydrogen Technologies engineers, and the process of mastering serial production itself requires more than 20 suppliers from Serbia, as well as the employment of professionals from various fields, such as locksmithing, electrical engineering, electronics, software development etc. Furthermore, the sales and the penetration of new markets create additional room for employing experts from the fields of economy, finance, marketing...

FINANCIAL

POTENTIAL

1. Mastering the process of producing engine decarbonizing machines to be adapted and offered to the automotive industry market, the vehicle and engine maintenance industry, as well as motor vehicle testing companies or any organization or individual recognizing its business and financial potential;

2. Developing its network of engine decarbonizing centers, as well the franchise concept of operations in the territory of Serbia, the region and Europe.

Since May 2016, what the first Engine Decarbonizing Center in Belgrade opened, providing the service and continuing the research and testing of the technology and the market, Hydrogen Technologies has been performing an average of 3-4 decarbonizing sessions a day. A large number of service owners from Serbia and the region have tested the technologies on their own vehicles and the majority of them have recommended it to their clients. The company is therefore negotiating about opening new engine decarbonizing centers in larger cities. The price of decarbonizing in Serbia amounts to RSD 3,000-8,000, depending on the engine volume, and the cleaning should be done after each 15,000 kilometers (the prices are considerably higher on the level of Europe.)

In September 2016, the Center was visited by interested purchasers from Great Britain, Germany, Macedonia and Croatia. A month later, the first shipments to Great Britain and Germany were contracted, and the machine was also sold to the Macedonian customer. For this reason and due to the inevitable need to put the machine in the market of the EU and beyond, the testing process for the purpose of acquiring the CE marking (safety certificate) was started and completed successfully.

Hydrogen Technologies has invested around EUR 100,000 in the development of the technology and the decarbonizing machine in the past 4 years. The machine costs EUR 10,000, and the great potential in the markets of Europe and the regions, as well as a rather small offer of similar technologies, is a sure indicator that the technology has a great potential for growth. Furthermore, the fact that environmental awareness is increasing, as is the awareness of the importance of reducing CO2 emission and making savings on every level, will make the development of this technology even more interesting in the next 10-20 years.

Thanks to

the technology's quality and safety, as well as the system of controlling the

process and the machine position, Hydrogen Technologies has already developed a

franchise system in this field in cooperation with a renowned Polish company,

to be offered to the market fairly soon, following the export of around 20

machines to the foreign market. They are planning to offer the same concept to

the local market, as well as to the countries of the region.

Most Important News

06.04.2024. | Agriculture

Preconditions for Placement of Fresh Blueberries and Dried Plums in Chinese Market Secured

16.04.2024. | News

Jovan Ciric, Leasing Director Retail MPC Properties – MPC Echo symbolizes our desire for good ideas and innovative endeavors to spread freely and bring about positive changes

16.04.2024. | News

10.04.2024. | Finance, IT, Telecommunications, Tourism, Sports, Culture

Creative Industry – What This Serbian Economy Sector Worth EUR 2 Billion Encompasses

10.04.2024. | Finance, IT, Telecommunications, Tourism, Sports, Culture

18.04.2024. | Industry, Finance

Here come the new hunters for Serbian gold – Australian Strickland Metals buys mining project on mountain Rogozna

18.04.2024. | Industry, Finance

16.04.2024. | News

Economy Fair in Mostar opens – 26 companies from Serbia exhibiting

16.04.2024. | News

18.04.2024. | Transport

Jovanovic: Purchase of Siemens trams produced in Kragujevac for GSP Beograd should be considered

18.04.2024. | Transport

Izdanje Srbija

Izdanje Srbija Serbische Ausgabe

Serbische Ausgabe Izdanje BiH

Izdanje BiH Izdanje Crna Gora

Izdanje Crna Gora

News

News