How Can the Right Heat Exchanger Technology Increase Your Energy Efficiency and Reduce CO2 Emissions?

Monday, 13.06.2022.

Monday, 13.06.2022.

13:57

13:57

With a foundation built on decades of experience, Alfa Laval have been developing innovative plate heat exchanger technologies that help businesses around the globe to optimize the use of energy in their operation processes.

Thanks to those technologies, which are used in numerous applications such as industrial refrigeration, data centres cooling, residential heating and many more, huge amount of energy can be saved every year, and as a result - the emissions of carbon can be significantly reduced.

And to achieve even greater effect Alfa Laval is supporting one of the main pillars for sustainability – the circular economy, by collaborating with partners and customers to ensure that every natural resource is used and reused in the most efficient way possible.

Clean Energy

Reducing carbon emissions will require a complete transformation of the global energy system. Investments in energy efficiency, renewable energy and carbon capture and storage (CCS/S) technologies are needed to reverse current trends.

Given the limited opportunities for decarbonisation in sectors such as oil and gas, power, refining, petrochemicals and cement, CCU/S will be critical to the future of the energy market.

Alfa Laval has been an integral partner in the development of many of the CCU/S equipment available. With a broad portfolio of heat exchangers, we help our customers meet the demands of this energy-intensive process, maximizing CO2 capture while minimizing steam consumption and media requirements.

The compressor refrigeration and heat pump industry is moving away from traditional refrigerants towards natural, zero-emission refrigerants. Alfa Laval has developed a wide range of heat exchangers specifically designed to cope with the demanding requirements of working with these refrigerants such as carbon dioxide, ammonia and propane.

Alfa Laval solutions can save 50 GW per year globally, contributing to a reduction of up to 25 million tonnes of CO2 emissions, helping to maximise energy efficiency. In addition, the company offers future-proof solutions for clean hydrogen production, fuel cells, carbon capture and energy storage, accelerating the transition to clean energy.

Waste heat recovery

Alfa Laval`s well-designed heat exchanger technology enables the capture and reuse of excess heat from existing processes for other purposes, such as heating or power generation.

In addition, it can also capture and reuse heat with lower potential. This is the case, for example, with heat recovery from data centres or from waste and geothermal water, where the excess heat can be used by means of heat pumps in, for example, district heating systems.

Saving more energy with the right heat exchanger technology

The payback time for an investment in waste heat recovery depends mainly on the efficiency of the heat exchangers and their associated life cycle costs. Therefore, the heat exchanger you choose plays a big role in calculating the potential savings. So, what are your options?

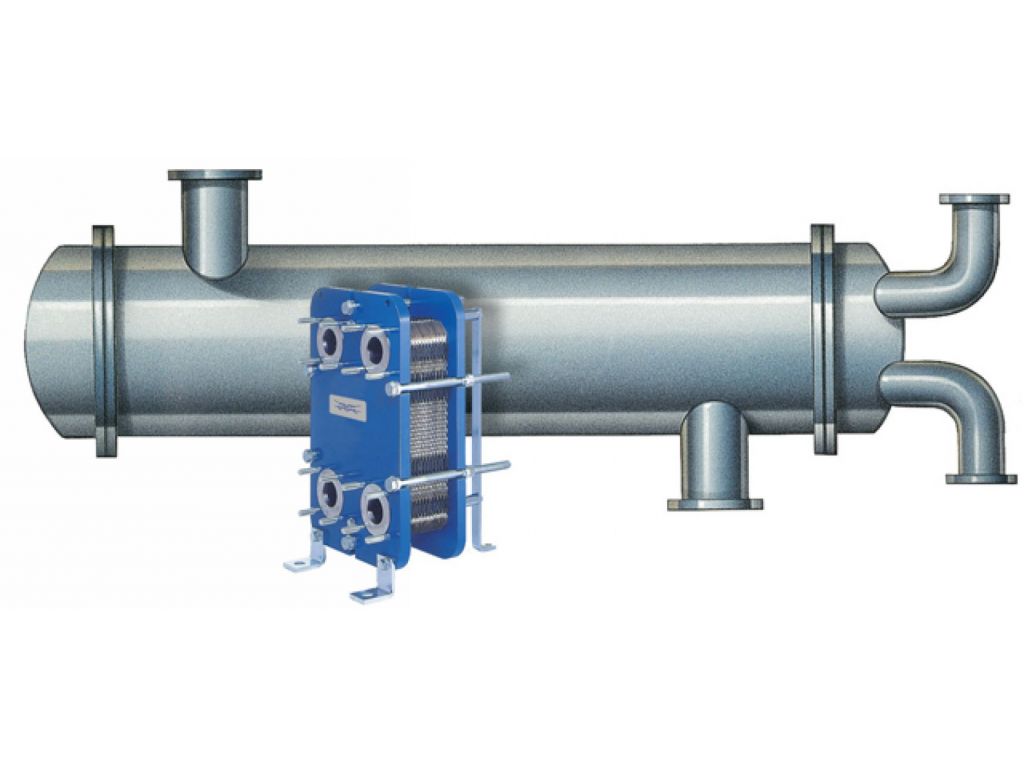

One, which is widely used in many comfort and industry applications for heating and cooling fluids, is the shell- and- tube heat exchanger. The shell-and-tube heat exchanger is designed and built for the toughest applications in chemical processing industries, oil & gas production, and power stations and it has its benefits, but is this the best option for you or is there another one, which can help you utilize better the energy you use.

If you think there must be another one, you are right. There is another technology with which you can achieve up to 20% better efficiency of heat recovery at a similar cost of the tubular heat exchanger and this is the Alfa Laval plate heat exchanger.

Choosing the significantly more efficient plate heat exchanger over the shell-and-tube heat exchanger will in fact bring several benefits to you:

1. Five times higher heat transfer efficiency

Plate heat exchangers are up to five times more efficient than shell-and-tube designs with approach temperatures as close as 1°F. Heat recovery can be increased substantially by simply exchanging existing shell-and-tubes for compact heat exchangers. The result is more energy being put back to use - energy that would otherwise have gone to waste.

2. Lower Capital costs

Plate heat exchangers weigh less than 1/16th the total weight of shell-and-tube exchangers and use 1/10th the floor space. That means immediate savings on shipping, handling, and installation costs. And PHEs can be assembled and disassembled on-site.

3. Lower maintenance costs

High-quality plate-and-frame heat exchangers can operate efficiently for over ten years without maintenance.

The heat transfer surfaces are easily accessible for inspection or mechanical cleaning, simply by removing the tightening bolts and rolling back the pressure plate. And special corrugated plate patterns ensure a high degree of turbulence over the whole plate, which not only reduces fouling but also makes cleaning very effective.

Frames can also be opened using standard tools, and there are no tube bundles to be pulled.

4. Less floor spaces

Plate heat exchangers weigh less than 1/16th the total weight of shell-and-tube exchangers and use 1/10th the floor space. That means immediate savings on shipping, handling, and installation costs. And PHEs can be assembled and disassembled on-site.

5. Easier capacity adjustment

Plate heat exchangers make it easy to adjust capacity to meet changing needs, simply by adding or removing plates, while retaining the existing frame. This is a major advantage in relation to shell-and-tube units, where capacity is fixed at the level decided on at the time of installation.

If you would like to learn more about how we can help your business grow and reach its sustainability potential, read here: Ubrzavanje održivih rešenja | Alfa Laval

OGRANAK ALFA LAVAL D.O.O. BEOGRAD

OGRANAK ALFA LAVAL D.O.O. BEOGRAD

Naš izbor

Most Important News

06.04.2024. | Agriculture

Preconditions for Placement of Fresh Blueberries and Dried Plums in Chinese Market Secured

16.04.2024. | News

Jovan Ciric, Leasing Director Retail MPC Properties – MPC Echo symbolizes our desire for good ideas and innovative endeavors to spread freely and bring about positive changes

16.04.2024. | News

10.04.2024. | Finance, IT, Telecommunications, Tourism, Sports, Culture

Creative Industry – What This Serbian Economy Sector Worth EUR 2 Billion Encompasses

10.04.2024. | Finance, IT, Telecommunications, Tourism, Sports, Culture

18.04.2024. | Industry, Finance

Here come the new hunters for Serbian gold – Australian Strickland Metals buys mining project on mountain Rogozna

18.04.2024. | Industry, Finance

16.04.2024. | News

Economy Fair in Mostar opens – 26 companies from Serbia exhibiting

16.04.2024. | News

18.04.2024. | Transport

Jovanovic: Purchase of Siemens trams produced in Kragujevac for GSP Beograd should be considered

18.04.2024. | Transport

Izdanje Srbija

Izdanje Srbija Serbische Ausgabe

Serbische Ausgabe Izdanje BiH

Izdanje BiH Izdanje Crna Gora

Izdanje Crna Gora

News

News