Trayal Corporation to Build Eco Park in Krusevac ŌĆō Facility for Treatment of Industrial Waste with New Technologies to be Raised Within Factory Complex

Sunday, 18.07.2021.

Sunday, 18.07.2021.

11:46

11:46

ŌĆō The developmental plans of the factory and the demands for the expansion of the production capacities, harmonization with the principles of the current circular economy which brings new features, but also the need for sustainable development, have led to the need for introducing new production facilities and processes and construction of new facilities. A new functional unit stands out within the complex, within which substantial interventions and construction of facilities for temporary storage and treatment of hazardous and non-hazardous waste are planned, whose purpose entails the implementation of high standards which primarily concern the protection and preservation of the space, which can be achieved through the implementation of the principles of sustainable development and in compliance with the legal regulations that pertain to this field ŌĆō says the urban plan, which was prepared by Centar za urbani razvoj i arhitekturu Paradigma d.o.o. from Krusevac.

The construction of a hall for thermal treatment of waste with a management-administrative part, a canopy for bioremediation, a handling platform and a substation are also planned. In order to enable the functioning of the planned facilities and complexes within the unit, the construction/extension of internal traffic routes, parking spaces for freight vehicles, a handling area and pedestrian lanes is also planned, whereas free areas are meant to feature greenery.

The construction of the hall for thermal treatment of waste with the management-administrative part is planned in the northern section. This is meant to be a free-standing facility, with two floors (including the ground floor), with dimensions of 100.76 m x 40.76 m. The gross area of the facility which is calculated into the occupancy index is 4,367.4 m2.

The ground floor is to feature: an entrance porch with stairs, a hallway with stairs, an office, a pantry, a hallway, an antechamber, two wardrobe rooms with shower cabins, two sanitary blocks (for men and women), two crawl spaces, a storage area, a preparatory section, an incinerator space, an electric arc furniture, a plasma facility, a handling space with a ramp, entrance porches with stairs and outer staircases. The upper floor, located in the western part of the facility is supposed to contain a hallway with stairs, a small kitchen, two sanitary blocks and three offices.

The construction of the bioremediation canopy is planned in the eastern part of this unit and its purpose is to be a storage space for bioremediation. This is a free-standing facility, with a ground floor, with dimensions of 30.50 m x 20.50 m. The gross area of the facility which is calculated into the occupancy index is 638.7 m2.

Next to the canopy facility, the plan features the handling platform, with dimensions of 30 m x 20 m.

The substation facility is set within the southwest part of the complex. It is a custom-made free-standing facility, with a ground floor, with dimensions of 16 m x 8 m and a gross area of 128.0 m2.

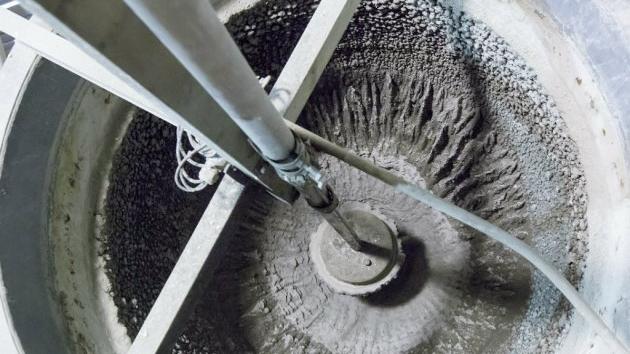

Plasma waste treatment

The total capacity of the facility for the plasma treatment of hazardous waste is 1,000 tons a year. The treatment of hazardous waste at the facility will be carried out through two lines, one for pyrolysis or gasification of waste, the other for glazing. The input materials are waste matters, which can be technologically incinerated at this facility. The treatment with the plasma technology and glazing procedures involves waste matters which can be treated in the incinerator due to the high content of chloride or fluoride, highly volatile metals, heavy metals etc.

In general, the process of gasification produces, as the end-product, a synthetic gas, a mixture of carbon-monoxide and hydrogen, whereas the glazing process produces glazed oxide materials, elemental metals, gases and dust, where, depending on the type and the quality of the input materials, metal content of up to 5% can be expected, whereas de-dusted glazed material can account for up to 95% of the batch.

I. M.

Trayal korporacija a.d. Kru┼Īevac

Trayal korporacija a.d. Kru┼Īevac

Na┼Ī izbor

Most Important News

06.04.2024. | Agriculture

Preconditions for Placement of Fresh Blueberries and Dried Plums in Chinese Market Secured

16.04.2024. | News

Jovan Ciric, Leasing Director Retail MPC Properties ŌĆō MPC Echo symbolizes our desire for good ideas and innovative endeavors to spread freely and bring about positive changes

16.04.2024. | News

10.04.2024. | Finance, IT, Telecommunications, Tourism, Sports, Culture

Creative Industry ŌĆō What This Serbian Economy Sector Worth EUR 2 Billion Encompasses

10.04.2024. | Finance, IT, Telecommunications, Tourism, Sports, Culture

18.04.2024. | Industry, Finance

Here come the new hunters for Serbian gold ŌĆō Australian Strickland Metals buys mining project on mountain Rogozna

18.04.2024. | Industry, Finance

16.04.2024. | News

Economy Fair in Mostar opens ŌĆō 26 companies from Serbia exhibiting

16.04.2024. | News

18.04.2024. | Transport

Jovanovic: Purchase of Siemens trams produced in Kragujevac for GSP Beograd should be considered

18.04.2024. | Transport

Izdanje Srbija

Izdanje Srbija Serbische Ausgabe

Serbische Ausgabe Izdanje BiH

Izdanje BiH Izdanje Crna Gora

Izdanje Crna Gora

News

News